Metal fenders offer a bunch of benefits over their plastic counterparts. They are often lighter, offer better coverage of the tire, the rolled lip reduces side spray, they generally look nicer, etc. One of the challenges of the fender though is the need to put more hand work into the install. My last post resulted in a few questions that made me realize our readers could use a little more info on some sheet metal working skills used to put holes in the fender. Part of installing the fender, lights and wires will often if not always require you to make holes in what are perfectly good fenders. Good technique and proper tools can make this a breeze, a couple of lazy steps could leave you with expensive scrap metal. I documented an install of a headlight on a bike that already had the rack and fenders mounted in place. If you are building from scratch it is often far easier to make all of the needed holes at the work bench.

Here are the basic tools you will need: Marker, Drill Bits (in the event that you did not get a step bit), Countersink, Round File, Step Bit, Center Punch, Stress Relief Grommets, Wooden Backing, Drill Motor

There are other tools out there, like a large hole punch made by Honjo, but these are the basic hand tools that many of you may already have, or can get at you local hardware store.

There are other tools out there, like a large hole punch made by Honjo, but these are the basic hand tools that many of you may already have, or can get at you local hardware store.

First step is to put your drill bit into the motor, think about where your holes will be, then remove everything that is in the way.

This includes you tire, the light, possibly the rack and any other accessories that may be in the way. If you get lazy and leave stuff in the way you have a high risk of wrecking stuff, it is not worth it, trust me.

This includes you tire, the light, possibly the rack and any other accessories that may be in the way. If you get lazy and leave stuff in the way you have a high risk of wrecking stuff, it is not worth it, trust me.

With everything you need stripped off, use the marker to make a mark where you want the holes. With lighting wires there is a bit more margin on the location. Mounting holes need to be precise. Taking the time to make the mark forces you to take a second and think twice (or more) about where you are making the holes

Once you are sure of the hole location use your center punch to make a small indent in the place you want to be the center of the hole. The indent will help to keep the drill bit from running all over your fender at the start of drilling. When you make the indent with the punch be sure to support the fender from behind with you hand and the block of backing wood.

Once you are sure of the hole location use your center punch to make a small indent in the place you want to be the center of the hole. The indent will help to keep the drill bit from running all over your fender at the start of drilling. When you make the indent with the punch be sure to support the fender from behind with you hand and the block of backing wood.

Without support from behind, the indent you make with the punch could end up damaging the fender more than intended. If you do not have a spring loaded center punch a sharp nail can substitute, but you may need a second set of hands to keep everything supported.

Without support from behind, the indent you make with the punch could end up damaging the fender more than intended. If you do not have a spring loaded center punch a sharp nail can substitute, but you may need a second set of hands to keep everything supported.

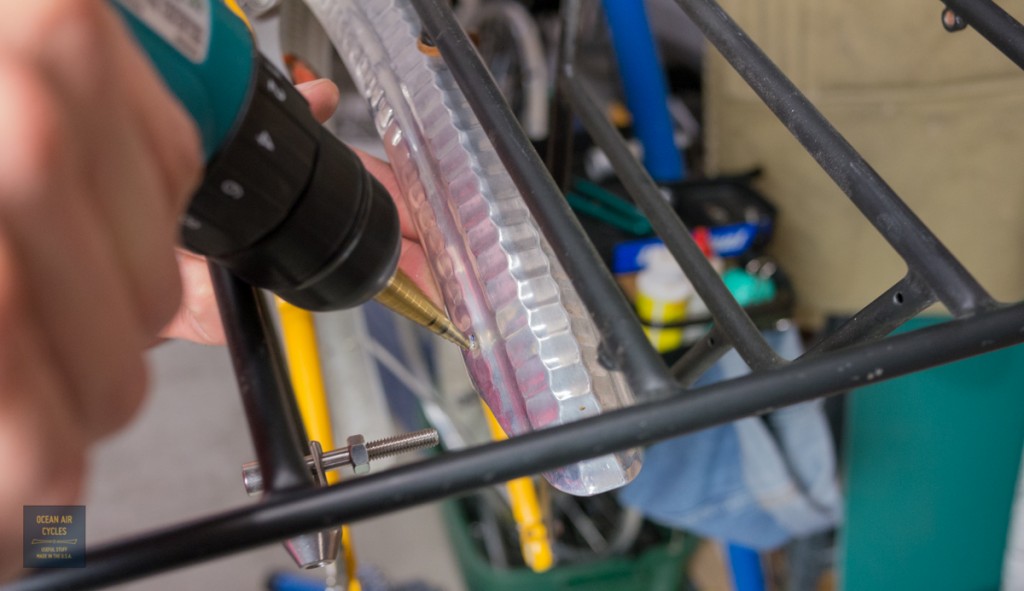

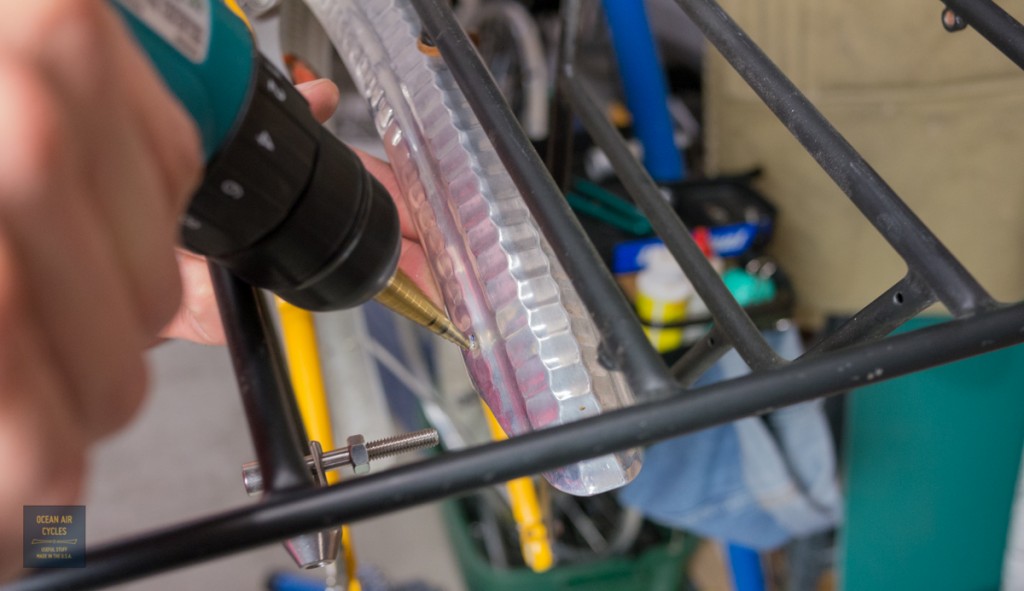

It is time to drill. If you have the step drill this will go a bit easier. These are made specifically for sheet metal and the way they take incremental cuts, as well as the shape of the cutting edge help to reduce the pressure needed to make the hole cut. If you are using traditional drill bits be sire to start with a small bit (hole), then move up to a bigger bit. Also be sure to back the hole with a wooden block.

With the step drill you do not need the wooden block and things are a bit easier. You can see the black lines I made on the bit. These mark the diameters where I want to stop. The black line makes it much easier to see on the spinning bit.

With the step drill you do not need the wooden block and things are a bit easier. You can see the black lines I made on the bit. These mark the diameters where I want to stop. The black line makes it much easier to see on the spinning bit.

This is what the hole should look like.

Nice and round, a tiny bit smaller then the final hole you want and there will be a metal bur around the edge. You can either use your countersink by hand or the round file to gently de-bur and clean up the edge of the hole. I am using the file in the picture below.

Nice and round, a tiny bit smaller then the final hole you want and there will be a metal bur around the edge. You can either use your countersink by hand or the round file to gently de-bur and clean up the edge of the hole. I am using the file in the picture below.

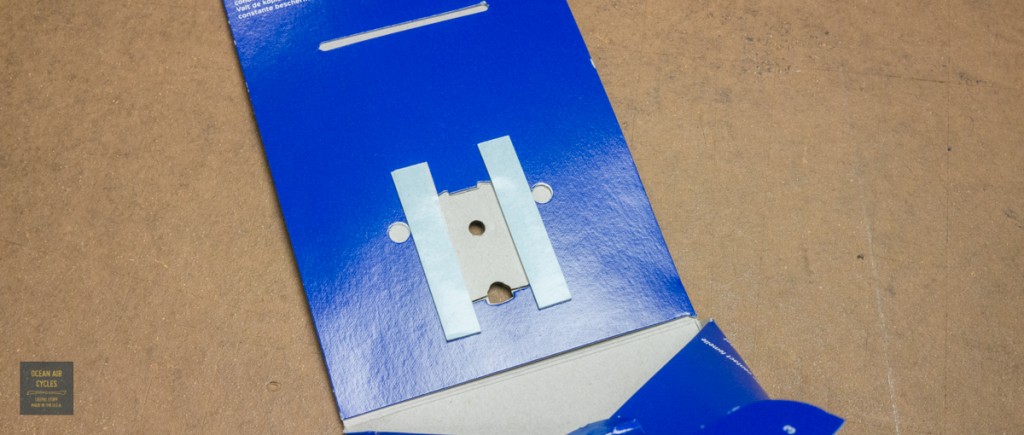

With the hole tuned up it is tie to push in the stress relief grommet. If this were a mounting hole it would be done. THe stress relief grommet protects the electrical wire from the sharp edge of the hole. Even with the edge filed smooth, the wire would likely wear through and fail from the vibrations of riding. The grommets can be bought in a variety of sizes at you local hardware store. They are usually found in the electrical section. They are shaped like tiny doughnuts with a groove cut in around the edges

With the hole tuned up it is tie to push in the stress relief grommet. If this were a mounting hole it would be done. THe stress relief grommet protects the electrical wire from the sharp edge of the hole. Even with the edge filed smooth, the wire would likely wear through and fail from the vibrations of riding. The grommets can be bought in a variety of sizes at you local hardware store. They are usually found in the electrical section. They are shaped like tiny doughnuts with a groove cut in around the edges

Every time I hold one I think of it as a tiny Death Star with Luke flying around the trench in an X-Wing. Yes that kid is alive and well in all of us I hope.

Every time I hold one I think of it as a tiny Death Star with Luke flying around the trench in an X-Wing. Yes that kid is alive and well in all of us I hope.

Push the grommet into the hole and work around the edges on moth singes to make sure that the grommet is centered with the top and bottom fully sandwiching the metal of the fender.

It should look the same on both sides, none of the lip caught in the hole. If you were lazy with the de-burring it will likely have taught your finger tips a lesson when working the grommet into place.

It should look the same on both sides, none of the lip caught in the hole. If you were lazy with the de-burring it will likely have taught your finger tips a lesson when working the grommet into place.

The hole is now ready and safe to pass your wire through, finishing off the rest of your lighting install.

If I were to insert this much detail into a single post it would end up incredibly long. I will do my best to expand steps like this where needed. Later this week there may be a post on grommets alone. Eventually I will cover wire terminations, and a bunch of other stuff that I take for granted. I was lucky to grow up in a mechanically inclined environment, then back it up with an engineering education, time in machine shops and countless hours keeping mechanical things running. This is my chance to share the knowledge. If at any point you think I jumped a step or need to explain something in more detail, hit me with a comment or message.

If I were to insert this much detail into a single post it would end up incredibly long. I will do my best to expand steps like this where needed. Later this week there may be a post on grommets alone. Eventually I will cover wire terminations, and a bunch of other stuff that I take for granted. I was lucky to grow up in a mechanically inclined environment, then back it up with an engineering education, time in machine shops and countless hours keeping mechanical things running. This is my chance to share the knowledge. If at any point you think I jumped a step or need to explain something in more detail, hit me with a comment or message.

Because much of this is second nature to me there will be things I skip, like eye protection. Not that I skipped it, but forgot to write it out. Eye and face protection are no joke when working with metal. Metal bits in your eye sucks, really bad, trust me. I usually wear a full face shield, it is easy and keep thing from getting in any of your head holes.

Now have fun punching holes in your perfectly good $100 plus new fenders, in the long run you will be happy with them.

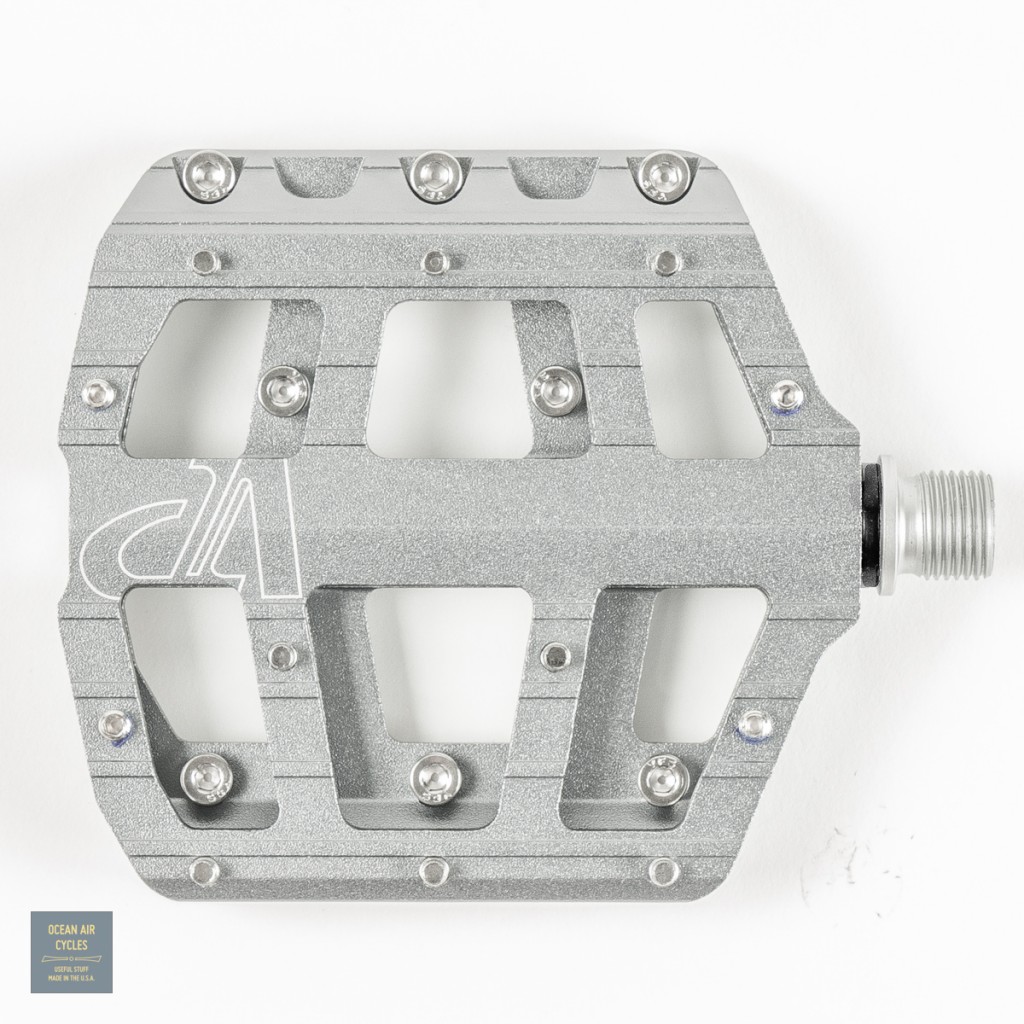

The vice is our favorite pedal for the money. The color options are really fun to add a touch of detail to your build. The next closest options that offer significantly better mechanical features cost roughly twice as much. I have helped a bunch of people onto these pedals over the last year. The only non-positive feedback was the wish that they came in Silver.

The vice is our favorite pedal for the money. The color options are really fun to add a touch of detail to your build. The next closest options that offer significantly better mechanical features cost roughly twice as much. I have helped a bunch of people onto these pedals over the last year. The only non-positive feedback was the wish that they came in Silver. Today is the last day of the lowest pre-sale pricing, tomorrow the price will go up another $10 before we settle in at the new $95 price point for the year. To see presale pricing you will need to add the pedals to your cart and use Coupon Code SVPVPS at checkout. While we can not advertise the price, I will say this is a smoking deal and below the wholesale price of most other thin flat pedals on the market.

Today is the last day of the lowest pre-sale pricing, tomorrow the price will go up another $10 before we settle in at the new $95 price point for the year. To see presale pricing you will need to add the pedals to your cart and use Coupon Code SVPVPS at checkout. While we can not advertise the price, I will say this is a smoking deal and below the wholesale price of most other thin flat pedals on the market.