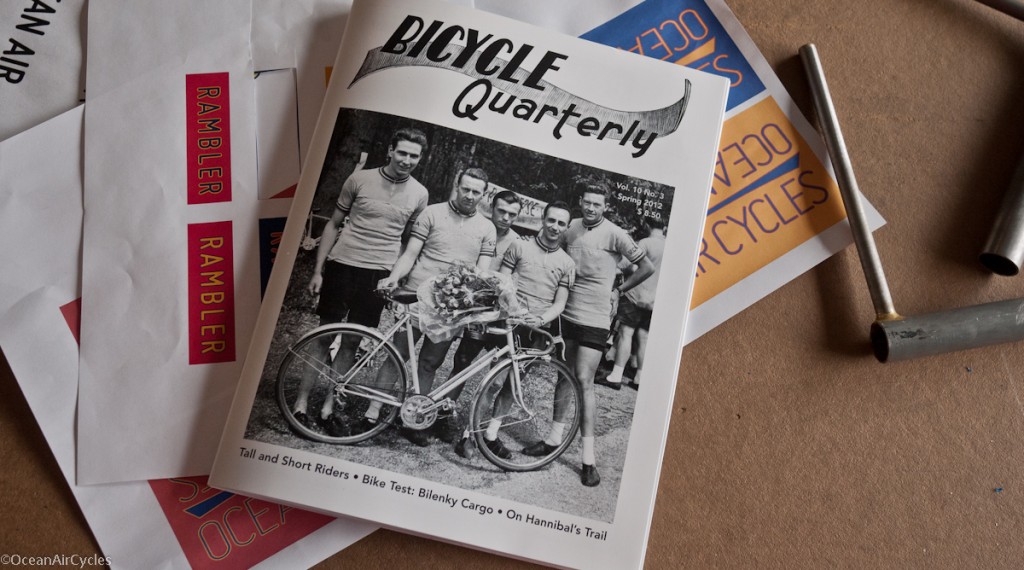

I am sure many of you, but maybe not all, who are readers here are likely familiar with Bicycle Quarterly, and the strong bias towards traditional French bicycles that they profess. BQ is one of the few sources of well thought information on bicycles outside of mainstream modern racing. If you have not yet heard of them, it is a worthwhile read. The Spring 2012 issue hit my mailbox yesterday. Every time I promise myself to read at a decent pace, and stretch it out for a couple of weeks. As usual I ended up reading about 90% of it last night.

This issue had some decent coverage and insights on the issues surrounding bike design for taller and shorter riders. This has always been an issue for me in trying to interpolate Jan’s reviews and comments into something that applies for the bikes in our household. Jan is around 6 foot tall and 160 lbs, and represents the average rider/part-time racer’s slim build. I am 6’3″ and my wife is 5’4″, both of average build and are at the opposite ends of the size range. Over years of riding and research I have been able to take the data from the averages and work out bicycles that perform quite well for her and I. This led to helping friends outside the averages get on bikes that suited their every day needs as well. This bank of experience led to my design of the Rambler line. There are many ways to get things to work on the smaller and larger sizes of bikes, some better than others.

This issue had some decent coverage and insights on the issues surrounding bike design for taller and shorter riders. This has always been an issue for me in trying to interpolate Jan’s reviews and comments into something that applies for the bikes in our household. Jan is around 6 foot tall and 160 lbs, and represents the average rider/part-time racer’s slim build. I am 6’3″ and my wife is 5’4″, both of average build and are at the opposite ends of the size range. Over years of riding and research I have been able to take the data from the averages and work out bicycles that perform quite well for her and I. This led to helping friends outside the averages get on bikes that suited their every day needs as well. This bank of experience led to my design of the Rambler line. There are many ways to get things to work on the smaller and larger sizes of bikes, some better than others.

The smaller bikes, sizes 56 and below, are designed to use the 650B wheel size. This wheel has a diameter between that of the common MTB tires and 700c road bikes. This leaves room to maintain a decent reach to the bars without making horrible compromises in the frame geometry. The front end maintains the desired handling characteristics without having toe-clip overlap. Toe-clip overlap is an occurrence at low-speed where the foot on the pedal and the front wheel can collide at the extreme turning points. These extremes do not often occur, but when they do, it can take the rider and bike to the ground. This possibility has been designed out of the bike. Another aspect of the design is Seat tube angle. I have kept it such that the seat will easily be set far enough back with commonly available components to keep the rider comfortable. Balancing all three of these parameters results in a bike that will comfortably fit the riders on the smaller side of average, allowing for the use of normal components to build a bike with either drop or upright handle bars. I think those familiar with the challenges of fitting smaller bikes will appreciate this design.

The larger sizes do not have the same space constraints with wheel size that the smaller bikes do. They have plenty of room for large 700c tires. These will offer the space for larger (up to 42mm) tires and fenders, that with a bit more rotating weight, will offer the gyroscopic stability that a larger rider may seek. This will be balanced with the front end geometry and long rear stays to flesh out a comfortable and stable bike. The challenge in taking the design above the averages is managing the flexibility of the frame, striking a balance between stability and the optimum resilience of the tubes. This is managed through steel tubing specification itself, and I have struck what I feel is a good balance for a rider and load total weight between 180 and 230 lbs.

The whole line is biased towards carrying a modest load on the front of the bike. This is so your every day necessities can be at hand without having to dismount and search around in a bag behind the saddle. Likewise you can keep an eye on your stuff. This style of loading requires subtle changes in the design of the bike that move away from the commonly available racing geometries of today’s mass market offerings. Ironically these changes, while accommodating the loading, result in a well-mannered bike with or without a load aside from the rider.

My designs throughout the size spectrum are confirmed by the reports in the issue of Bicycle Quarterly. Both the historical accounts well as reviews of recent interpretations covered in this issue, confirm my design philosophy and decisions. While I have complete confidence in my designs it was reassuring to have many of the aspects of my design affirmed in print. A big thank you to Jan Hine for his pas, current and future efforts with this publication.