Earlier this week I headed out with a couple of buddies on a two day tour on the central coast of California. The trip was originally conceived by two different friends who ended up having to pass on the trip, and that is a shame, as it was a fantastic ride. Mike, Jefe and I met up Monday Morning to take the Surfliner (Amtrak) up the coast to the small coastal station of Surf. Day one was the ride to Buelton, camp overnight, and then over the mountains and down the coast home. Pictures, as always will tell most of the story:

View of “The Ranch” from the train, this strech of open coast is all privately owned and off limits for most of us. I dream often of being able to ride and surf there. Beautiful open land, the way this stretch of coast has been for hundreds of years.

View of “The Ranch” from the train, this strech of open coast is all privately owned and off limits for most of us. I dream often of being able to ride and surf there. Beautiful open land, the way this stretch of coast has been for hundreds of years.

Surf Train Station, no Cell coverage, nothing but you, the beach and a road out. Not a place you are likely to end up by accident.

Surf Train Station, no Cell coverage, nothing but you, the beach and a road out. Not a place you are likely to end up by accident.

Out of the coastal fog, through Lompoc and heading down Santa Rosa rd. This is an incredible example of the hundreds of miles of country roads the California central coast has to offer.

Out of the coastal fog, through Lompoc and heading down Santa Rosa rd. This is an incredible example of the hundreds of miles of country roads the California central coast has to offer.

Yes it was hot, and consensus was clear, it was time to stop and sample the local “grape juice”!

Yes it was hot, and consensus was clear, it was time to stop and sample the local “grape juice”!

To help keep things light we ate in restaurants, Buelton is home to a few good ones, and we picked Firestone Brewery. Sorry no Pics, hunger was over riding the creative side of the brain. The Burger was fantastic, I could have had two, but logic prevailed. The Flying Flags campground was pretty nice. Although, next time we all agree that we would rather push a little further into the ride for the first stop.

To help keep things light we ate in restaurants, Buelton is home to a few good ones, and we picked Firestone Brewery. Sorry no Pics, hunger was over riding the creative side of the brain. The Burger was fantastic, I could have had two, but logic prevailed. The Flying Flags campground was pretty nice. Although, next time we all agree that we would rather push a little further into the ride for the first stop.

The next morning started with a few miles to wake up and grab some breakfast in the next town of Solvang. The whole town is Dutch themed, one of those places you have to visit to really understand. Bellies full, we pushed off.

The next morning started with a few miles to wake up and grab some breakfast in the next town of Solvang. The whole town is Dutch themed, one of those places you have to visit to really understand. Bellies full, we pushed off.

This was the start of the real climbing on Refugio Rd., 4 miles of sustained 10-14% grades. The legs were willing, the heat was climbing, and I will admit, that I opted to hike-a-bike through plenty of sections. I was carrying too much weight for this leg of the trip. I had looked at the map and elevations, but did not really appreciate it until I was all the way immersed. It was hard going up, I was focused on making the top, and the camera never came out for the next hour.

This was the start of the real climbing on Refugio Rd., 4 miles of sustained 10-14% grades. The legs were willing, the heat was climbing, and I will admit, that I opted to hike-a-bike through plenty of sections. I was carrying too much weight for this leg of the trip. I had looked at the map and elevations, but did not really appreciate it until I was all the way immersed. It was hard going up, I was focused on making the top, and the camera never came out for the next hour.

Over the top and well above the coastal fog. At the break between the fog and horizon you can just make out the top of the channel islands. The ride down was a blast, but Refugio Rd is in terrible condition, many potholes. I elected to keep my hand on the bars and not fool around with the camera.

Over the top and well above the coastal fog. At the break between the fog and horizon you can just make out the top of the channel islands. The ride down was a blast, but Refugio Rd is in terrible condition, many potholes. I elected to keep my hand on the bars and not fool around with the camera.

Heading into Santa Barbara. As we worked our way South East along the coast, we were flirting with the edge of the fog bank the whole way. The summer temperatures were cool and crisp, but the regular tailwind never made an appearance.

Heading into Santa Barbara. As we worked our way South East along the coast, we were flirting with the edge of the fog bank the whole way. The summer temperatures were cool and crisp, but the regular tailwind never made an appearance.

The last view back up the coast before the final 10 mile push home.

The last view back up the coast before the final 10 mile push home.

The trip was perfect, the company, weather, terrain etc. This is sure to be a stepping stone for more local rides like this. The whole thing was comfortably pulled off in just over 36 hours. I could have brought less, we could have done a few things differently, but it all worked out. My legs are the only part that is not in a state of recovery this week. I am still processing my thoughts on the trip and will be sharing them over the coming weeks as I make some changes in my gear. The Rambler continues to exceed my expectations for this type of riding, and we are all looking forward to getting back out there.

Thanks Mike and Jefe for helping to make it all happen.

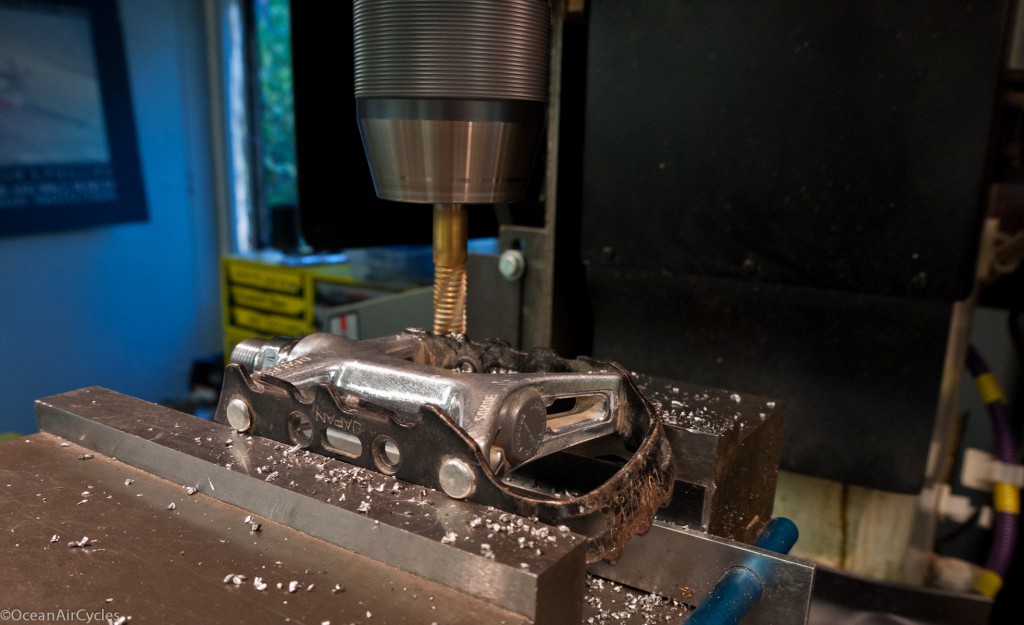

A simple M6 coupler replacing the nut on the brake shoe stud. Then I drilled out the PB Superflash mounting bracket to 6mm and bolted it on. Yes, that simple.

A simple M6 coupler replacing the nut on the brake shoe stud. Then I drilled out the PB Superflash mounting bracket to 6mm and bolted it on. Yes, that simple.