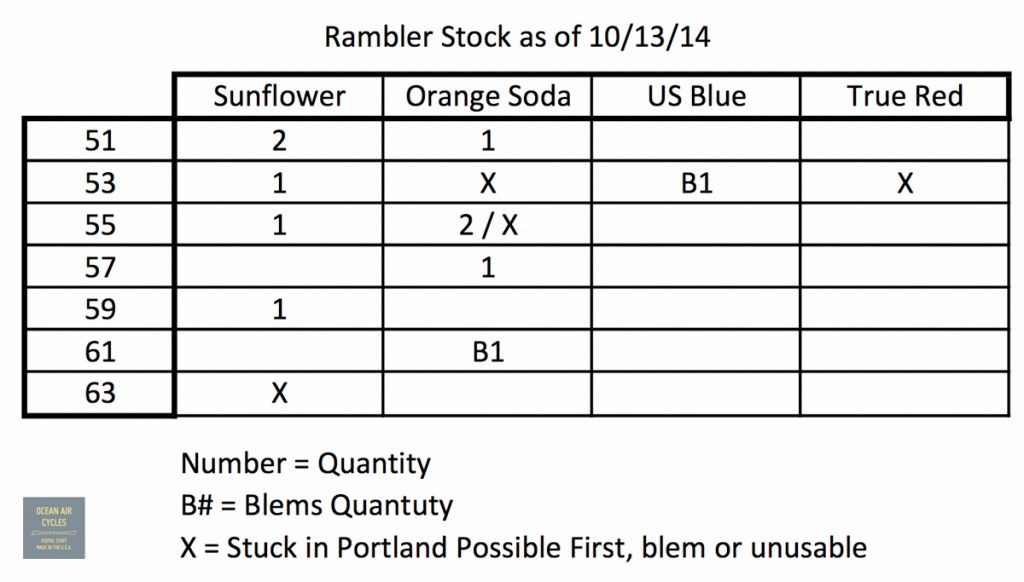

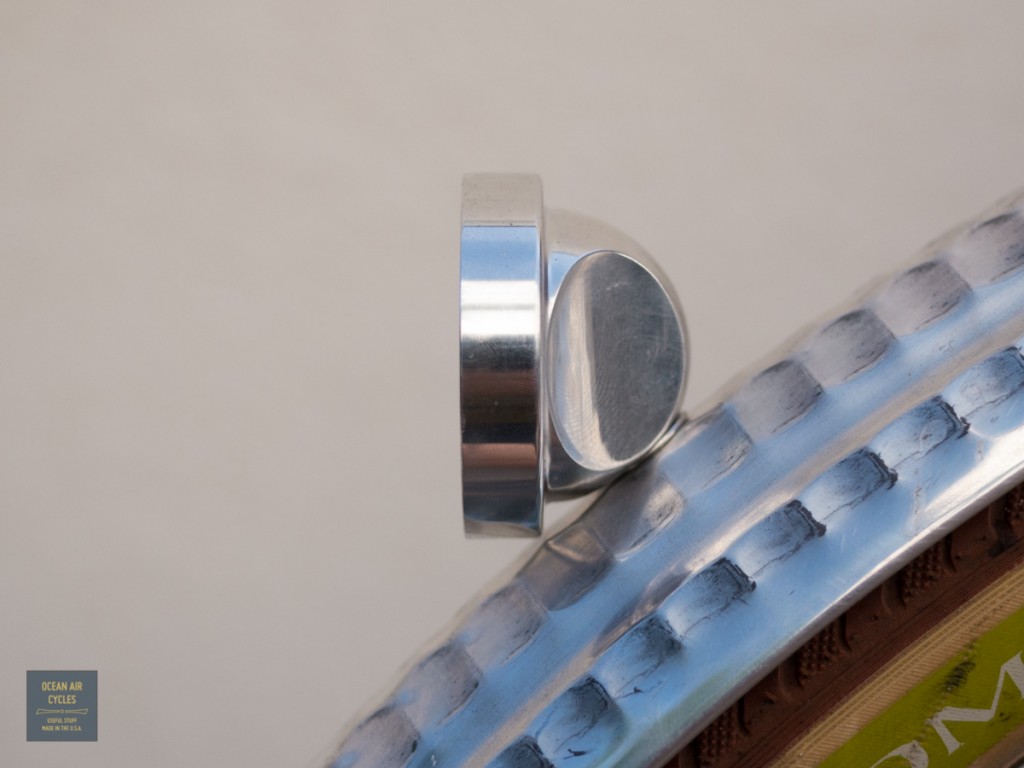

We are getting to an interesting turning point with the business as Rambler stock is getting lower. But before we bore you with the details, a couple pics to tantalize you with what your Rambler could be:

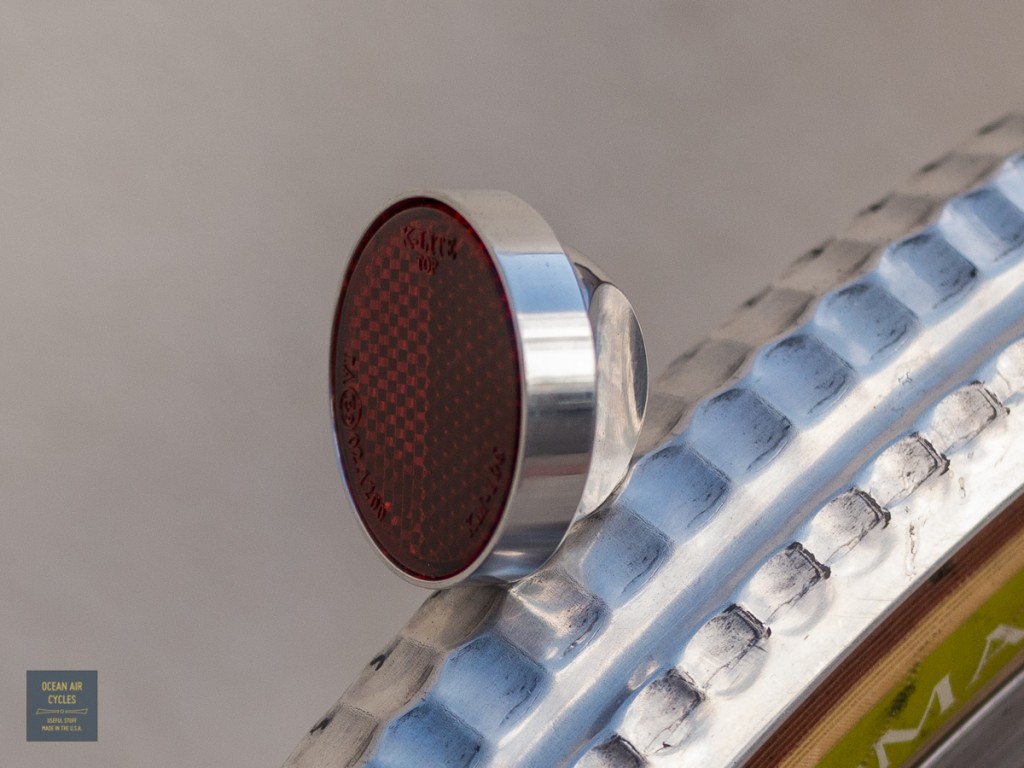

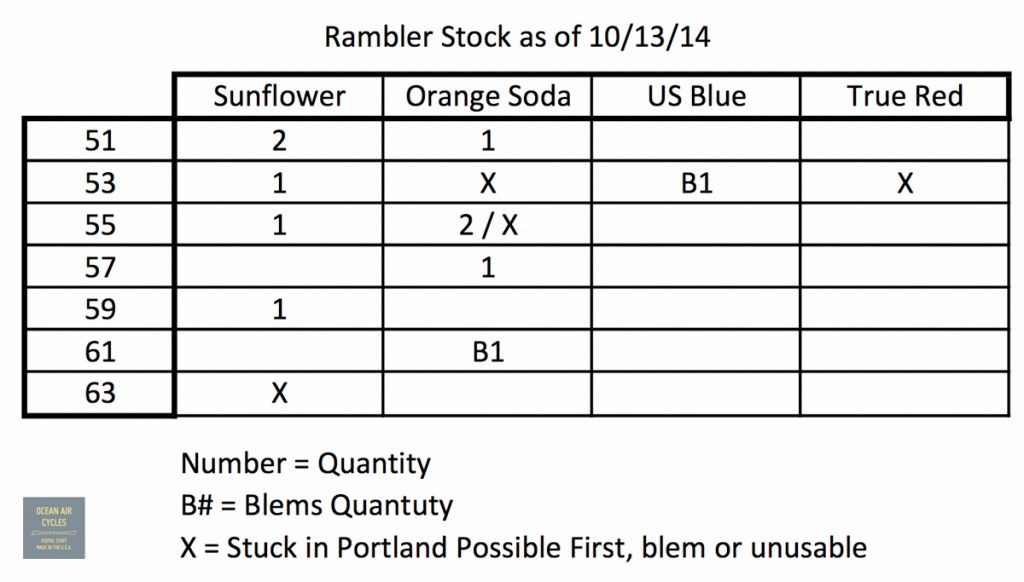

The current stock falls into a couple of categories summarized in the matrix below. Nothing in the box means we have sold through that size/color combination in this run. A number indicates stock on hand. The letter “B” followed by a number indicated the number of blemish frame sets on hand in this combination. Then there are the “X” frames. These four have been caught in a combination of coating re-work and small business Purgatory. The only thing setting them free will be cash flow from sales of a few more frame sets. From there we can inspect them and determine if they are first quality, blemishes or worst case un sellable. I can tell you, the line for the Sunflower 63 is about 5 customers deep right now.

The current stock falls into a couple of categories summarized in the matrix below. Nothing in the box means we have sold through that size/color combination in this run. A number indicates stock on hand. The letter “B” followed by a number indicated the number of blemish frame sets on hand in this combination. Then there are the “X” frames. These four have been caught in a combination of coating re-work and small business Purgatory. The only thing setting them free will be cash flow from sales of a few more frame sets. From there we can inspect them and determine if they are first quality, blemishes or worst case un sellable. I can tell you, the line for the Sunflower 63 is about 5 customers deep right now.

What does this mean? If you have been thinking of getting a Rambler, and we have your size on hand it is probably a good time to buy one. Will there be more Ramblers? It is quite likely. How we will get there is still not quite certain. The demand is growing rapidly, I wish I had about 10 size 63 and 10 more 57. Our current builder has minimums that push our cash flow to the limits and beyond. I dream of doing 75-100 more Ramblers for Spring, but not sure how to get there yet, pre-sales, Indegogo, bank loan, etc. Sorting that out over the next couple of months. Short of a massive pile of cash falling from the sky, it will most likely be the middle of 2015 before a new batch of Ramblers are ready to go.

What does this mean? If you have been thinking of getting a Rambler, and we have your size on hand it is probably a good time to buy one. Will there be more Ramblers? It is quite likely. How we will get there is still not quite certain. The demand is growing rapidly, I wish I had about 10 size 63 and 10 more 57. Our current builder has minimums that push our cash flow to the limits and beyond. I dream of doing 75-100 more Ramblers for Spring, but not sure how to get there yet, pre-sales, Indegogo, bank loan, etc. Sorting that out over the next couple of months. Short of a massive pile of cash falling from the sky, it will most likely be the middle of 2015 before a new batch of Ramblers are ready to go.

There is the issue of healing our wounds from this past round, learning some lessons, and adjusting sourcing and coating. Some colors just did not work, hence all the Blems. Some colors may come back, there may be new ones. There are some business aspects, supply chain, increased quality control, contracts with rework clauses clearly spelled out, insurance for stuff destroyed in re-work, and all the other less exciting details of the business. This will all start to be sorted in the coming months.

What is certain? If you see your size in the matrix above, and you want a Rambler it would be a good time to get one. They are great bikes, customer feedback has been unanimous. The only thing changing in the next round is possibly less color choices. The design is solid. Need more inspiration, everybody loves bike pics?

What else do we have in the works? On the new front we have t-shirts, yes more than one design, custom printed bandannas, still searching for a leather contractor, possibly Rambler specific racks some new touring cap variants. The standards are still her as well: Docena bags on a quarterly basis, Bandannas, Double Weave Kerchiefs, Farm and Field knives, Caldera Cone Stoves Silver Vice pedals, Tires etc. We are constantly increasing the number of items on hand.

What else do we have in the works? On the new front we have t-shirts, yes more than one design, custom printed bandannas, still searching for a leather contractor, possibly Rambler specific racks some new touring cap variants. The standards are still her as well: Docena bags on a quarterly basis, Bandannas, Double Weave Kerchiefs, Farm and Field knives, Caldera Cone Stoves Silver Vice pedals, Tires etc. We are constantly increasing the number of items on hand.

Thank you for helping us get this far. Without your continued support we would not have made it this far.

Also, there are still two frames waiting to go at Blue Lug in Japan and Free Range in Seattle has two or three, one of which is built up and ready to ride

This round of bags will start production in about two weeks and we are projecting for a Late February delivery. Pricing is still holding at 2014 levels, $250 gray with color trim, $260 for multi cam and $275 for the Harlequin (My Favorite)

This round of bags will start production in about two weeks and we are projecting for a Late February delivery. Pricing is still holding at 2014 levels, $250 gray with color trim, $260 for multi cam and $275 for the Harlequin (My Favorite)